During a restoration it is all about the details when it comes to starting an automobile engine for the first time. So many factors can prevent the engine from running properly or for that matter, at all. Failure to double check every connection can cause serious damage to a new engine. Again, it is all about the details.

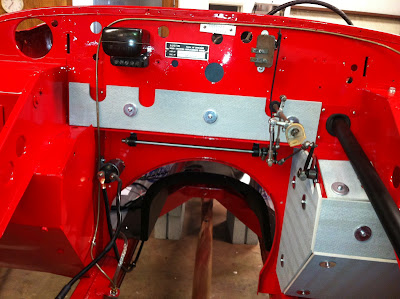

When I ordered the wiring harness, I didn't realize that the overdrive wiring was not included. The harness shown at the top of the photo the right is the new overdrive wiring.

I also connected the oil filter today. It was not an easy task. I actually had to remove the filter bracket in order to assemble the system. Spin-on filter adapters are available, but we must go with the original.

I also wired the distributor and coil today. The plug wires and coil wire on the original distributor cap were attached by set screws that penetrated the wires, thus making the connection. A bit more difficult than current technology, but again, it is original.